R&D Capabilities

At HGGaoli, we're always looking for cutting-edge technologies that enable a more intelligent, connected, and human-friendly world. Over the years, we’ve been dedicating to the research and development of our independent technologies, with which we’ve achieved completely independent production of our core elements and components.

-

40+Provincial

1 National Science & Technology Progress Award, 2 Third Prizes, and more than 40 Provincial and Ministerial Science & Technology Progress Awards

-

1000+Intellectual Property

More than 800 intellectual property rights applied and 540+ granted

View Intellectual Property Rights -

8Innovation Platforms

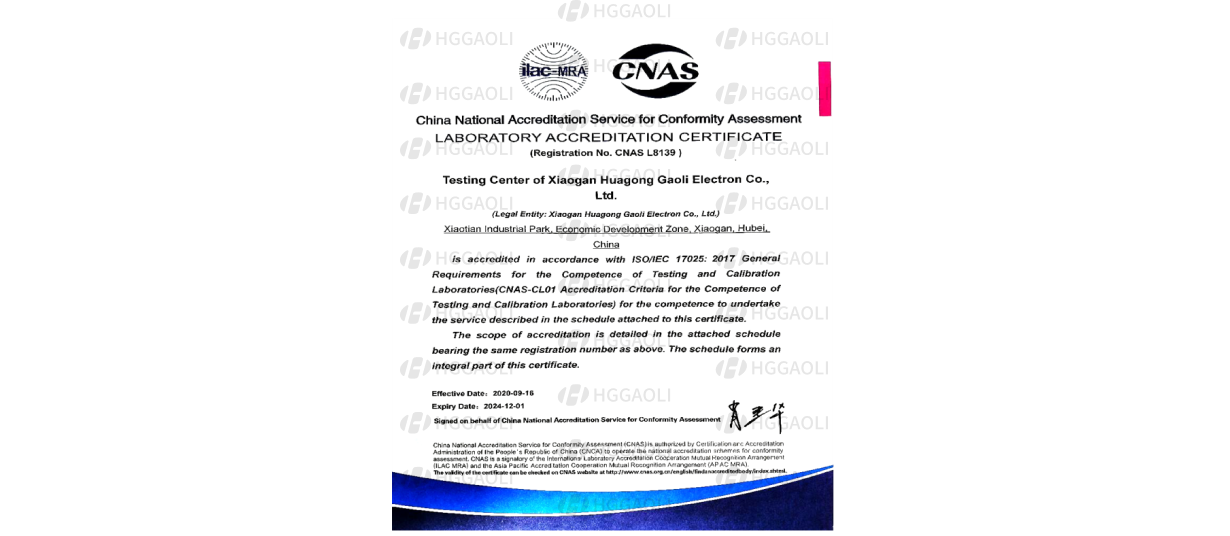

8 Innovation platforms, including the Engineering Research Center for Functional Ceramics with MoE, National CNAS Laboratory, and Academician Workstation, etc.

View Certifications

HG Perception Technology Research Center

HG Perception Technology Research Center focuses on sensor development needs in all fields, including intelligent vehicles, AI, IoT, etc. Through the R&D of multi-functional and intelligent-controlled sensors, the center adds more variety to sensor-rich solutions.

The Research Center enhances our technological innovation and new product development capabilities, while driving shared development of the industrial chain.

Testing Ability

CNAS Accredited Laboratory

HGGaoli’s testing center is a CNAS Accredited laboratory, UL WTDP laboratory, TÜV Witness laboratory, and has been accredited by key customers including GM, Geely, BYD, NIO, GM-Wuling, SAIC MAXUS, JAC, Seres, Changan. Possessing more than 200 professional testing equipment, the testing center aims to provide more sophisticated technical services for markets and customers.

-

Salt spray

High-Low Temperature test

Water bath test

Three comprehensive tests

10+Environmental Tests -

Dust-proof test

Waterproof test

Drop test

Vibration test

34+Performance &Safety Protection -

3D printing

Vickers hardness

Eletron microscope scanning

X-ray inspection

10+Chemistry&Precision Analysis

Testing Abilities

Intelligent Manufacturing

Industry-leading Manufacturing Execution System

At HGGAOLI, we believe in data-driven innovation and informed decision based on data analysis. Therefore, we have adopted an industry-leading manufacturing execution system(MES) that optimizes the manufacturing process by monitoring, tracking, documenting, and controlling the entire production life cycle.

Through the collecting, analyzing and utilizing of MES data, we have achieved highly automated operation, agile and flexible production with full-process traceability, and created synergy between the upstream and downstream.

Production Capacity

-

Sensing BU

-

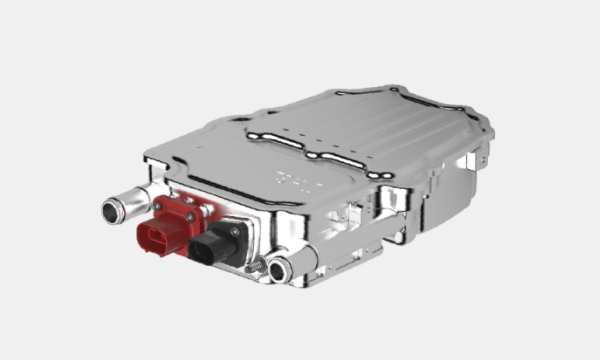

PTC Thermal Management BU

-

-

1.5+Billion PiecesAnnual capacity over 1.5 billion pieces

-

4.6+Million PiecesDaily capacity over 4.6 million pieces

-

-

-

11+ Million SetsAnnual Capacity over 11 million sets

-

35,000+setsDaily Capacity over 35,000 sets

-

Quality Management

Quality as the lifeline of an enterprise

We believe that quality is the lifeline of an enterprise, and therefore we strictly monitor and control our manufacturing processes to ensure all parts and products are of high quality. With unremitting pursuit of quality excellence, we have been certified to IATF 16949, ISO 9001: 2015, ISO 14001, ISO 45001, and our products have been certified by USA UL and NA CUL, VDE, CQC, etc.