IMR (In-Mold Roller)

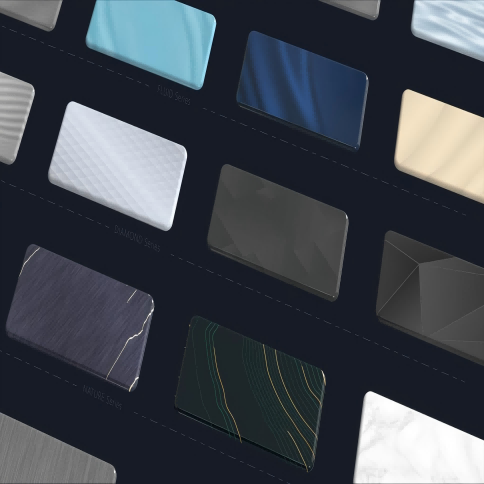

IMR (In-Mould Decoration by Roller, also referred to as In-Mold Roller), a type of high-end IMD technology, is mainly used for applying decorative and functional coatings to molded plastic products

-

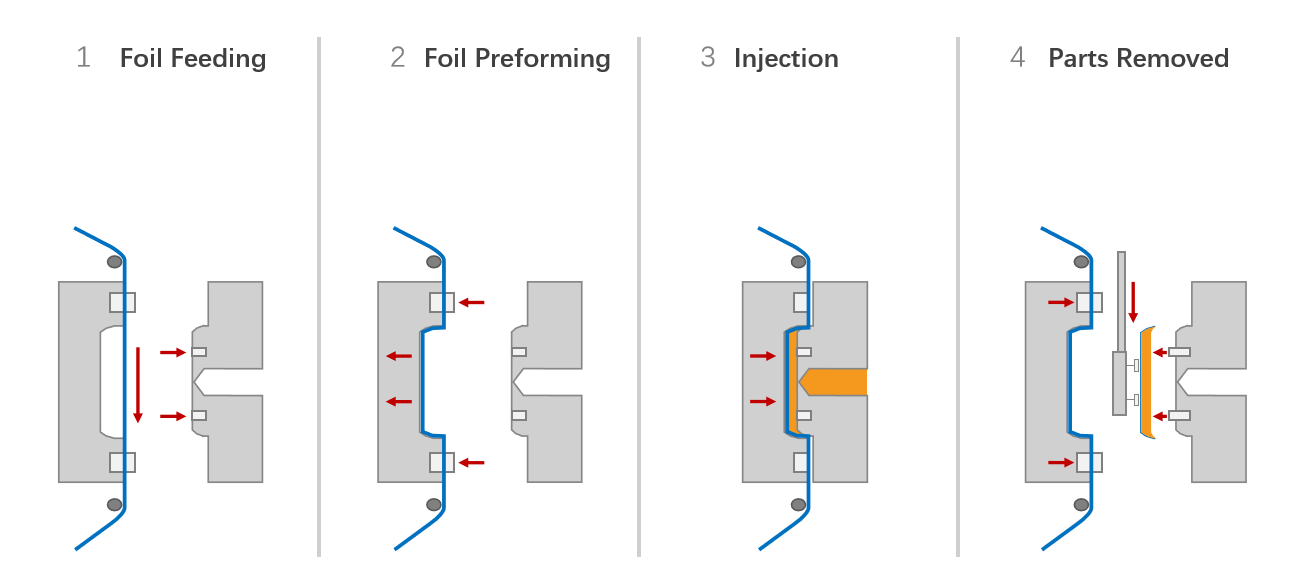

Detailed Process

Decorative and functional patterns are at first printed onto the IMD foil through a high-precision printer, after which the foil will be fed to a specialized injection molding tool and get precisely positioned in the cavity. At last, under the high temperature and pressure of the plastic raw materials in the mold, patterns on the foil will be transferred to the surface of the molded plastic products.

-

Applications

①Surface of household appliances

②Automotive interiors

③Smart home appliances

④3C consumer electronics -

Advantages

①Add variety to plastic surface design, greatly optimize appearance and texture

②Customized, diversified and specialized appearance design

③Environmental-friendly, efficient, and cost-effective

IMR Process

IML (In-Mold Label)

-

About IML

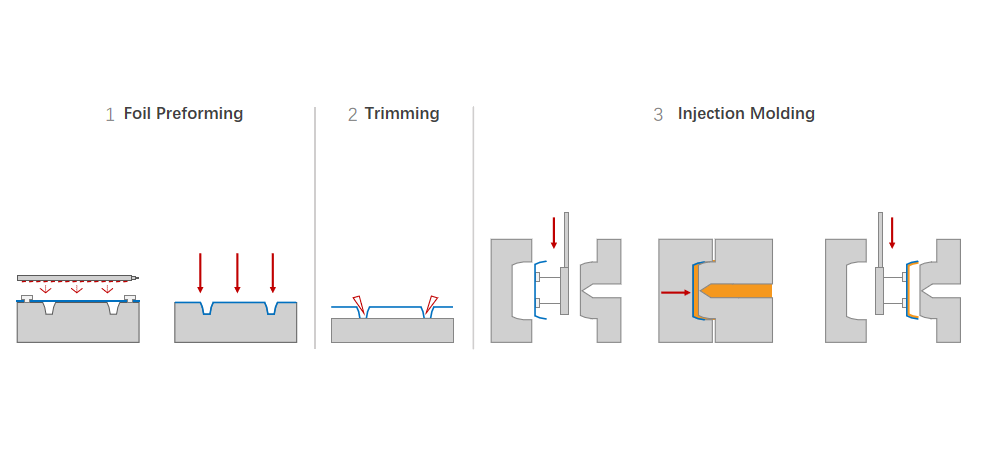

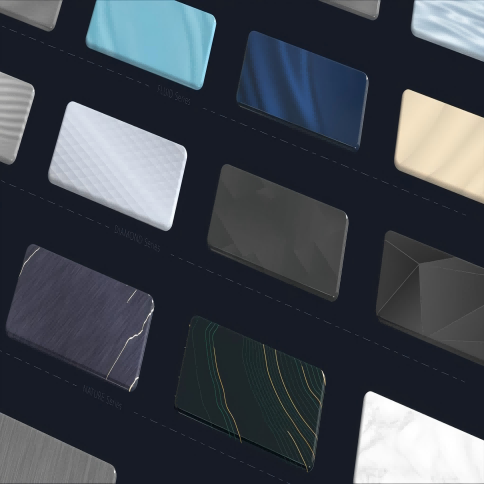

IML (In-Mold Labeling) can be used to achieve surface design with 3D geometry and backlighting effect. During IML process, the film is printed, preformed, cut and then finally placed in the injection molding tool for production.

-

Applications

①Decorative&control panels of smart home appliances

②Automotive interior trims with natural texture or backlighting

③Light-transmitting plate of EV's exterior decoration

④3C electronics, laptop housing, cellphone back housing

⑤Collectible trading cards, toys, gamepads

⑥Panel of NEV's charging pole

INS (Insert Molding)

-

About INS

INS (Insert Molding) uses vacuum forming or compressed forming to achieve three-dimensional stretching of the inserted film, after which the inserted film is cut to the product's shape and then get precisely positioned in the mold's cavity for injection molding

-

Applications

Decorative and control panels of smart home appliances

Automotive interior trims with natural texture or backlighting

Light-transmitting plate of EV’s exterior decoration

3C electronics, laptop housing, cellphone back housing

Collectible trading cards, toys, gamepads

Panel of NEV’s charging pole

IML/INS Process

Contact Us

A world-leading supplier of sensors and PTC heaters

Always adhere to our commitment to customers